Electronic Assembly

We assemble complex electronic systems with precision and care—from wire harnesses and cable assemblies to fully integrated enclosures. Our team supports high-mix builds, rigorous quality standards, and seamless integration with mechanical and electromechanical components.

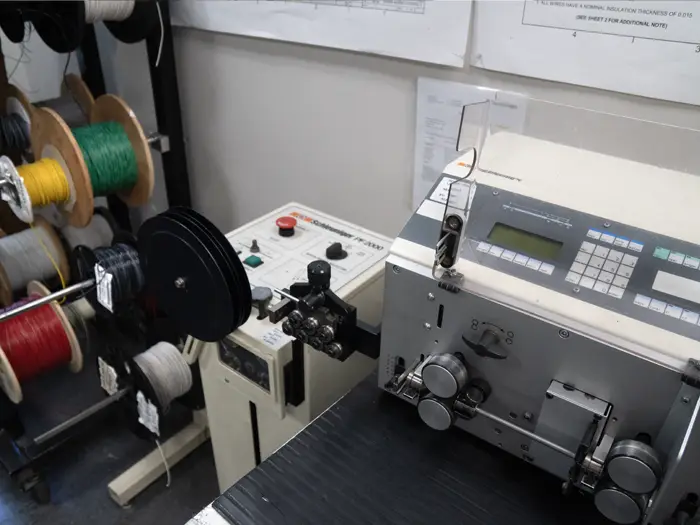

Precision Cable Assembly & Fabrication

We build a wide range of custom cable assemblies in-house—from simple point-to-point jumpers to complex multi-branch harnesses and high-performance RF, fiber optic, coaxial, and high-voltage configurations. Our technicians work with a broad spectrum of cable types and connectors, including M12, Molex, JST, Deutsch, ribbon, battery, USB, Ethernet, and triax. Every step—cutting, stripping, crimping, soldering, overmolding, and testing is performed under strict process controls to ensure quality, consistency, and reliability across production runs.

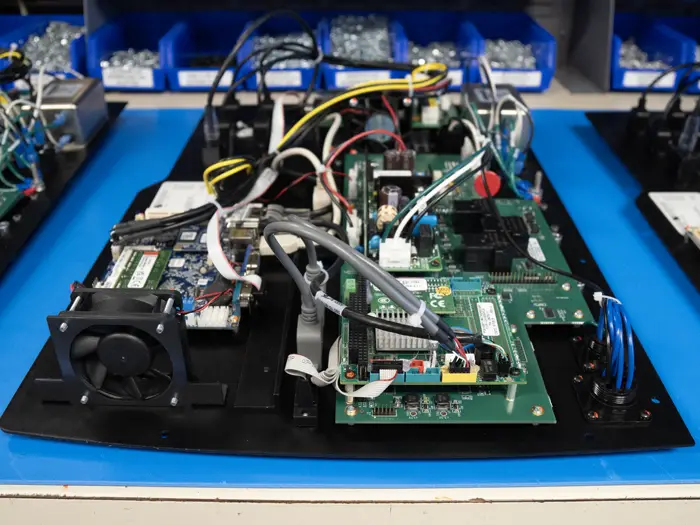

Industrial Computer Manufacturing

We design, build, and ship complete computer systems for industrial applications. Originally developed to power our own CNC machines and automation products, these rugged, field-proven systems are now available for integration into other equipment and environments. Each unit is assembled and tested in-house to ensure dependable performance under demanding conditions. From motion control to data processing, our computers offer a reliable, scalable platform for OEMs and system builders who need high-quality, industrial-grade solutions.

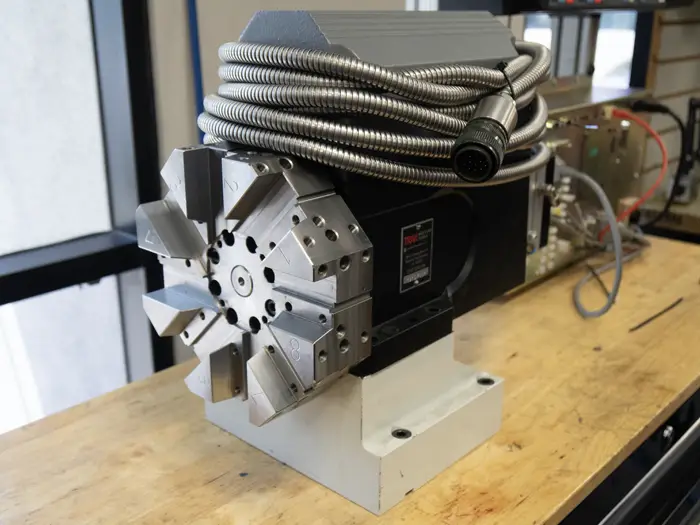

Electromechanical Assembly Manufacturing

We manufacture complete electromechanical assemblies that combine precision-machined components, electrical systems, and control interfaces into fully integrated, production-ready units. Developed to meet the rigorous demands of our own CNC and automation products, this capability is now available to OEMs and equipment builders. From sensor and actuator integration to cable routing and control panel wiring, every assembly is built and tested in-house to ensure performance, reliability, and seamless function in the field.

Motor Assembly

SWI Manufactured Systems specializes in building a wide range of custom motors to meet specific requirements. We manufacture motor encoders entirely in-house—including the PC boards, code wheels, and reader heads—ensuring tight control over quality and performance. Each assembly undergoes rigorous testing, often using custom-built fixtures designed to validate functionality under real-world conditions. This integrated approach allows us to deliver reliable, high-performance motor assemblies tailored to exact specifications.

Built-to-Spec Cable Solutions

We manufacture a wide variety of cable assemblies to meet the demands of industrial, aerospace, defense, medical, automotive, and telecom applications. Our scalable manufacturing lines support everything from low- to high-volume production, enabling fast turnarounds without compromising quality. Capabilities include discrete wire assemblies, multi-conductor cables, coaxial and RF cables, shielded and jacketed configurations, and complex wire harnesses.

We also offer in-house overmolding, ultrasonic welding, and custom connector machining to accommodate specialized requirements. Every assembly is built to spec with full process documentation and 100% electrical testing to ensure performance and reliability in the most demanding environments.

Electronic Support

Our Electronic Support Department plays a critical role in both customer satisfaction and manufacturing continuity. It maintains a ready inventory of exchange units, enabling rapid overnight replacements when customers encounter issues in the field. Internally, the team provides technical expertise to support production processes that require electronic intervention or troubleshooting. It also partners closely with Customer Service to assist with field diagnostics and installations, ensuring customers get responsive, knowledgeable support when they need it most.