PCB Manufacturing

High-precision PCB manufacturing with in-house capabilities, fast turnaround, and proven reliability across every build. Our process supports full-scale production with consistent quality at every stage.

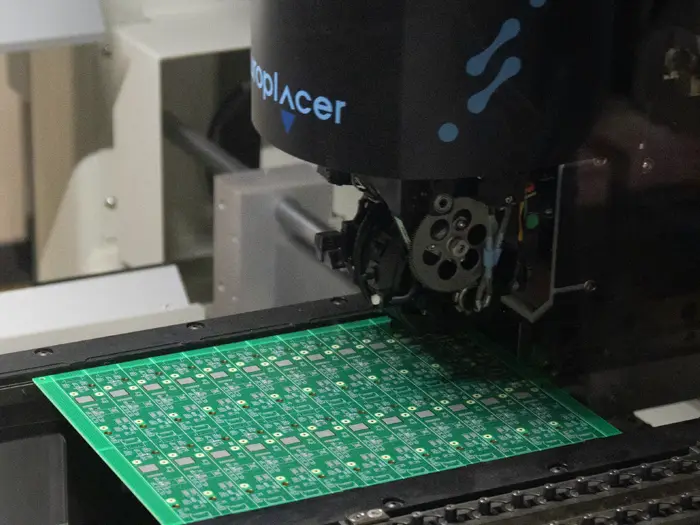

Automated SMT Assembly

We assemble complex printed circuit boards with precision and consistency as part of our broader systems integration work. Our SMT lines support fine-pitch components, BGA, and mixed-technology builds on rigid or flex PCBs. Surface mount components are placed with high-speed accuracy and soldered using tightly controlled reflow profiles. Every board goes through optical inspection and testing to ensure reliable performance.

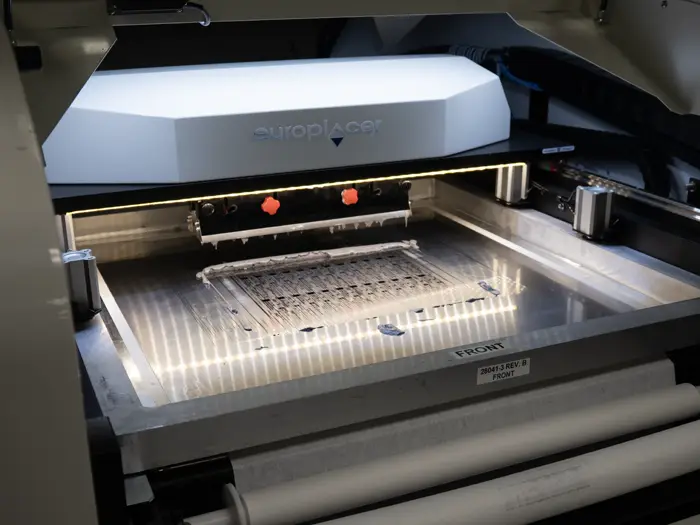

Selective Soldering for THT Components

For through-hole components and mixed-technology assemblies, we use selective soldering to achieve precise, high-reliability joints without affecting nearby components. Selective soldering eliminates the variability of hand soldering while ensuring consistent quality. It's an essential step in builds where through-hole durability is critical.

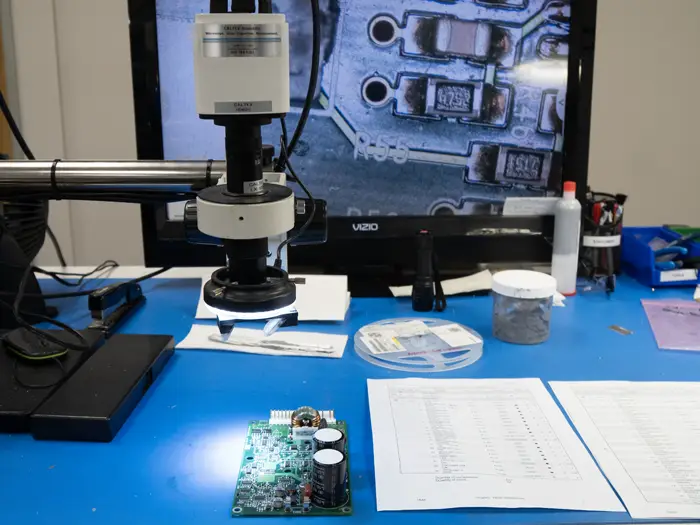

Precision Inspection & Quality Verification

We use high-resolution digital microscopy to perform detailed inspections of every assembly, verifying solder joint quality, component alignment, and overall board integrity. This process is especially critical for fine-pitch devices and high-density layouts where visual accuracy is key. Backed by thorough documentation and traceability protocols, our inspection workflow ensures that each build meets exacting quality standards before moving forward in the process.