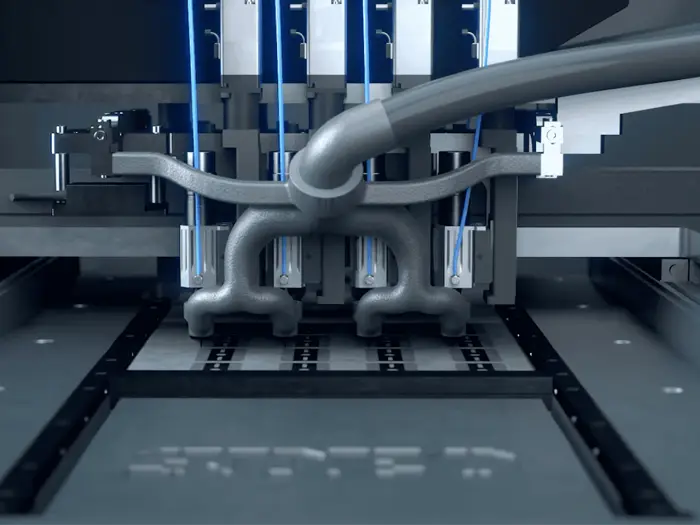

Saffron Metal 3D Printer

Built to meet the demands of production metal 3D printing, with tightly integrated mechanical and control systems.

Saffron is a production-grade metal 3D printer, designed in partnership between SWI Manufactured Systems and 3DEO, and fully built at our facility in Rancho Dominguez, California. From concept to completion, every physical aspect of the machine was manufactured and assembled by SWI. The project showcases our ability to turn complex engineering designs into fully integrated, working systems—quickly, precisely, and reliably.

Bringing Saffron to life required a combination of CNC machining, control manufacturing, 3D plastic printing, and mechanical assembly—all performed in-house. The full build included over 200 manufactured components and more than 600 sourced parts, organized into 30+ assemblies. Our team coordinated every step, from precision part fabrication and wiring to final system integration.

Project Details

- State-of-the-art 3D Metal Printer

- Designed in partnership with 3DEO

- Built by SWI Systems

- Operations employed: machining, control manufacturing, 3D plastic printing, mechanical assembly

- Over 600 items purchased

- Over 200 items manufactured

- Over 30 assemblies

As a metal additive manufacturing platform, Saffron demanded high reliability across motion systems, powder handling, and thermal control. We built and tested each subassembly to meet those demands, ensuring smooth operation, long-term durability, and alignment with 3DEO's functional requirements.

This project is a clear example of what SWI delivers: vertically integrated manufacturing of complex, high-performance equipment. We combine technical depth with real-world execution to bring sophisticated systems to life.